What are the problems in the phosphating process of slag-free phosphating agent?

Release time:

2022-08-09 09:56

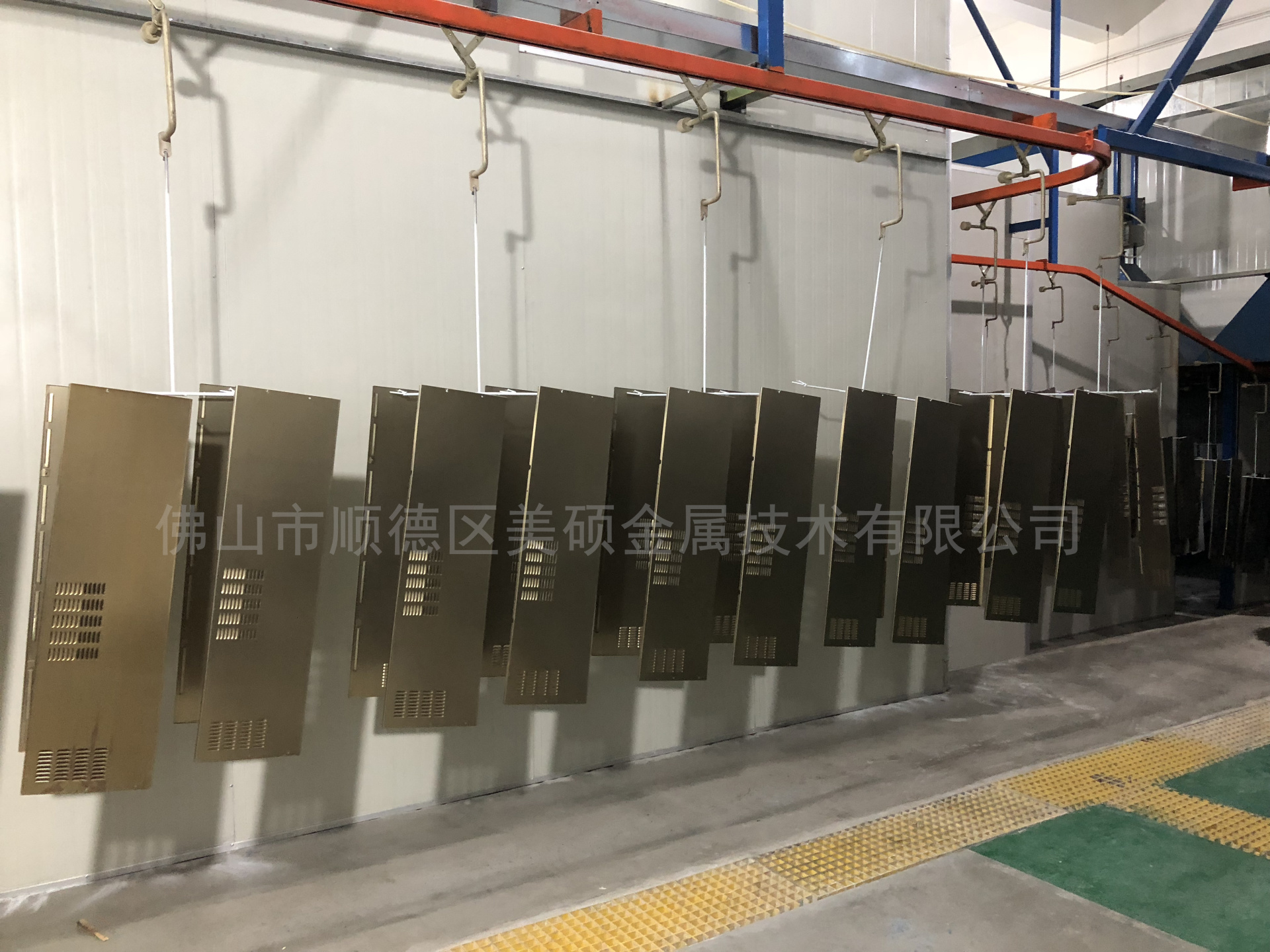

slag-free phosphating agentIt is a new type of zinc phosphating agent and a revolutionary technological breakthrough to the traditional zinc phosphating agent. It can be used at room temperature without slag and form a gray phosphating film. Slag-free phosphating is a process in which a metal reacts with dilute phosphoric acid or acid phosphate to form a phosphate protective film. So, as a new type of phosphating agent, slag-free phosphating needs to be controlled in order to achieve the best, in order to better produce high-quality products, let's take a look.slag-free phosphating agentWhat are the problems in the phosphating process?

slag-free phosphating agentPhosphating process If the process parameters are not properly controlled, there will be uneven phosphating film, rust, hanging ash, sediment and other phenomena, how to avoid these phenomena?

In the slag-free phosphating, the more common problem is that the surface of the workpiece is uneven in color after phosphating, and even has obvious mottling phenomenon. The main reason is that the surface of the workpiece is not well pretreated, not thoroughly cleaned, and there are residual oil stains or rust spots. The solution to this phenomenon is to thoroughly remove oil, rust and clean the workpiece before phosphating.

Phosphating film rust poor rust, the main reason for the total acid phosphating low, low promoter, phosphating time is too short, or surface aging. The solution is to detect the total acidity and the accelerator AC is very delicious. According to the test results, add slag-free phosphating agent and slag-free accelerator to ensure sufficient phosphating time: 12-15 minutes for tank immersion and 3-5 minutes for swimming immersion. No slag phosphating selection excellent quality table adjustment.

Phosphating film is dusty and has sediment. The main reason is that the accelerator is too high. The solution is: slag-free phosphating accelerator is a special accelerator. It is absolutely not allowed to use ordinary zinc phosphating accelerator. The accelerator is added according to the feeding method of adding a small amount of frequently and many times. A large amount of accelerator is not added at one time.

Non-slag phosphating agent, phosphating agent

Other News

2023-04-12

2023-02-08

2023-01-10